TECHNOLOGY

Agro technology

Irrigation in open ground

A closed production cycle based on a 4-pole crop rotation of the main tomato crop improves soil quality and reduces the use of agrochemicals. We use alfalfa cultivation as a natural siderate, sapropel application to the soil to improve drainage and increase fertility, and deoxidation of the soil with safe fertilizers. We use innovative approaches in greenhouse cultivation with full climate control of tomato seedlings and robotic outdoor transplantation.

Moisture-saving drip irrigation technology for tomatoes and onions, as well as hunter systems for long-term alfalfa crops with water supply from the Shardara reservoir, make it possible to obtain a sustainable harvest of all crops on time for processing at the cluster plants.

To build a sustainable ecosystem, we are developing contract farming with training in intensive technologies for growing and storing fruit and vegetable products. We need 60,000 tons of high-quality fruits, melons and vegetables every year.

If you have any questions about agro futures, please contact Yuri Bondarev yuriy.b@agriqa.asia

Low-volume hydroponics

The 21.2-hectare glass industrial greenhouse complex in Shardar is equipped with LED crop illumination with spectrum control to improve crop photosynthesis while reducing power costs. Cultivation on substrates in isolated climatic zones with full control of irrigation, CO2 nutrition, biosecurity and pollination, protection of plants from diseases using Dutch technologies.

Additionally, it is planned to build a glass industrial greenhouse for vertical cultivation of strawberries, salads and other crops with LED harvest lighting in the Alatau cheese. For open ground, seedlings are grown with seed germination chambers and an automatic seeding line in cassettes for further transplantation into fields.

Processing

Evaporation technologies

The tomato paste production process includes cleaning, crushing, heating (to deactivate enzymes and separate the juice), vacuum concentration, and sterilization. The plants can also process melons and fruits into purée using a small evaporator. The main technological stages are as follows:

- Preheating (Pressing):

- Cold Break: Tomatoes are heated to . This method preserves the bright color and active enzymes, enabling the recovery of high-quality juice.

- Hot Break: Tomatoes are heated to . This method is more commonly used for the production of ketchup and sauces.

- Concentration:

Tomato juice is concentrated in vacuum evaporators. The vacuum lowers the boiling point, helping to preserve vitamins and pigments. - Sterilization:

The finished paste is sterilized by adjusting temperature (approximately at pH below 4.2) and holding time to eliminate microorganisms. - Filling and Packaging:

The sterilized paste is cooled to and filled into aseptic containers—1,000-liter big bags and 200-liter drums with polyethylene liners.

AGRIQA turnkey plants based on Italian technologies from Ing. A. Rossi (formerly Rossi & Catelli) operate as fully integrated production lines. They feature a hydrotechnical transport system with four-stage raw material washing, an in-house water treatment system, and auxiliary units for cooling, steam generation, cleaning, power supply, and wastewater management.

Shock freezing

IQF (Individual Quick Freezing) technology is an individual fast freezing process in which individual pieces of a product freeze so quickly that they do not stick together, preserving their shape, taste and nutritional properties. This method uses an intense air flow (fluidization layer) in tunnel freezers, which allows for ultrafast freezing, preventing the formation of large ice crystals that damage the structure of the product during normal freezing.

Drying technologies

At the AGRIQA fruit-processing plant, two primary dehydration technologies are used:

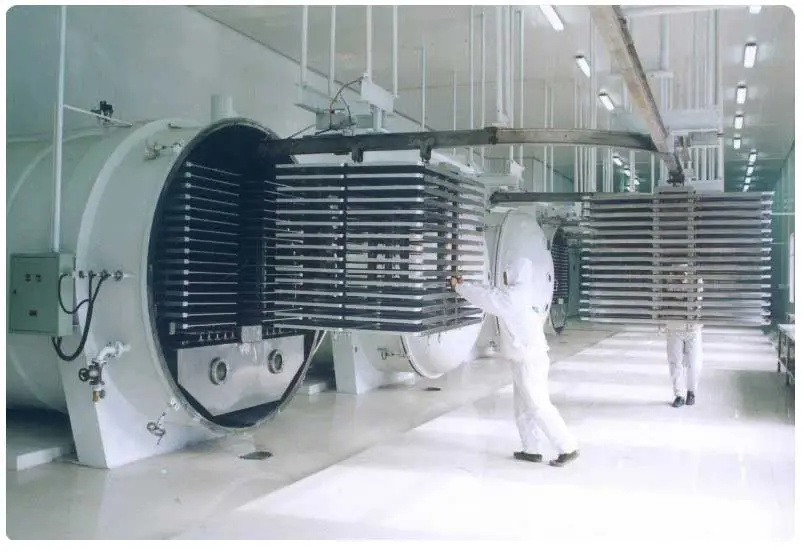

- Vacuum and Freeze-Drying Technology (Lyophilization):

This dehydration method removes moisture from products by first freezing them and then causing the ice to sublimate—transitioning directly from solid to vapor—under vacuum conditions. The process preserves the product’s nutritional value, flavor, and appearance, as it takes place at low temperatures, unlike traditional heat-based drying. The workflow includes freezing, vacuum drying, and subsequent packaging.

This process removes moisture from raw materials by exposing them to a flow of heated air. The hot air transfers heat to the product, causing moisture to evaporate, after which the moisture-laden air is discharged from the drying chamber. This method is used for drying wood, agricultural raw materials, food products, and other materials across various types of equipment, such as cabinet dryers, belt dryers, and tunnel dryers.- Vacuum and Freeze-Drying Technology (Lyophilization):